Ishidi lensimbi engagqwali

Ukucaciswa

Okubalulekile:Ibanga lokudla SS 304 316, ithusi, njll

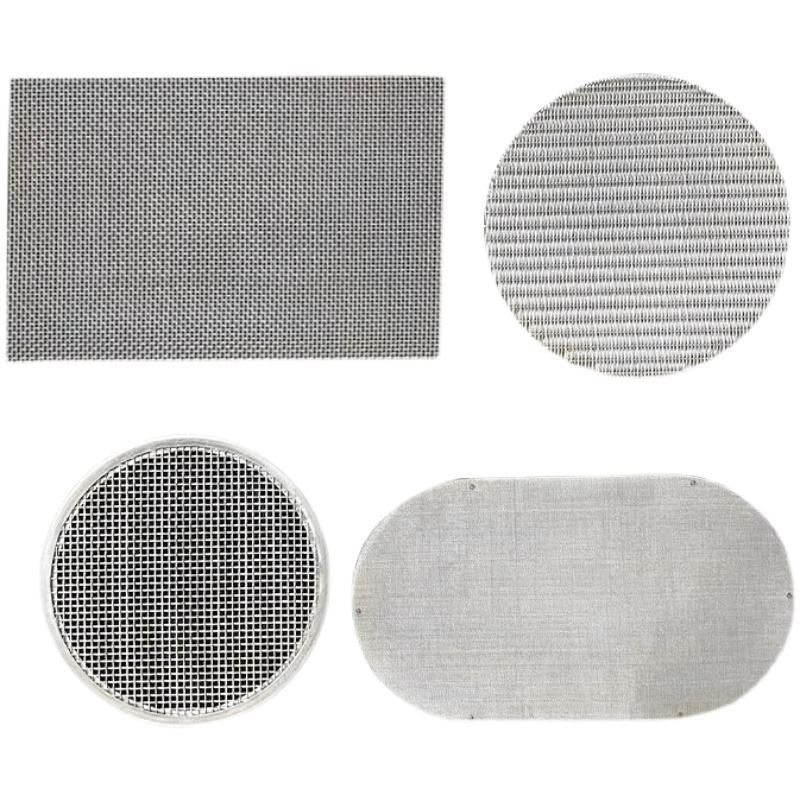

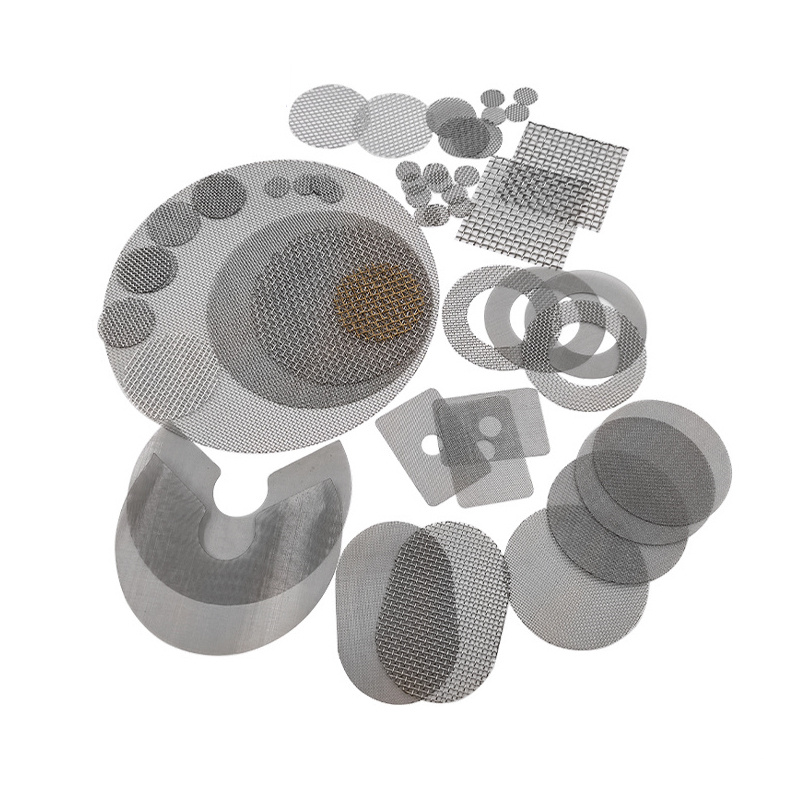

Isimo:Umumo oyindilinga, umumo ongunxande we-toroidal shape, ukwakheka kwesikwele, ukwakheka okusaqanda okunye okukhethekile

Isendlalelo:Isendlalelo esisodwa, izendlalelo eziningi

Yini i-sintered mesh?

I-Sintered wire mesh yenziwa ngokunqwabelanisa izintambo eziningi zensimbi engagqwali ezinongqimba olulodwa zohlobo olufanayo noma ezihlukene, ngemva kokucwiliswa, ukucindezelwa, ukugingqika nezinye izinqubo, zenziwa ngokusakazwa nesixazululo esiqinile ngemva kokudubula kwe-vacuum ku-1100°C. .Isihlungi esisha esinamandla amakhulu wokusebenza kanye nokuqina okuphelele.I-wire mesh yesendlalelo ngasinye inobubi bamandla aphansi, ukungaqini kahle, kanye nesimo semeshi esingazinzile, futhi ingafanisa ngokunengqondo futhi idizayine usayizi ongenalutho, izici zokungena kanye namandla wento, ukuze ibe nokunemba okuhle kakhulu kokuhlunga kanye nokubambezeleka kokuhlunga., Amandla emishini, ukumelana nokugqoka, ukumelana nokushisa kanye nokucutshungulwa, ukusebenza jikelele kusobala kungcono kunezinye izinhlobo zezinto zokuhlunga ezifana ne-sintered metal powder, i-ceramics, i-fiber, indwangu yokuhlunga, njll.

I-Sintered wire mesh ihlukaniswa ngokwamazinga ahlukene kanye nezakhiwo ze-wire mesh, ikakhulukazi ezihlanganisa i-wire mesh enezingqimba ezinhlanu, i-multi-layer metal sintered wire mesh, ipuleti elibhoboziwe le-sintered wire mesh, imbobo yesikwele ye-sintered wire mesh kanye nohlobo lwe-mat sintered wire mesh.

Izici ze-sintered mesh

1. Amandla aphezulu kanye nokuqina okuhle: Inamandla aphezulu emishini namandla acindezelayo, ukucubungula okuhle, ukusebenza kwe-welding nokusebenza komhlangano, futhi kulula ukuyisebenzisa.

2. Ukunemba okufanayo nokuzinzile: Ukusebenza kokuhlunga okufanayo nokungaguquki kungafinyelelwa kukho konke ukunemba kokuhlunga, futhi i-mesh ayishintshi ngesikhathi sokusetshenziswa.

3. Indawo esetshenziswa kabanzi: Ingasetshenziswa endaweni yokushisa engu -200 ℃ ~ 600 ℃ kanye nokuhlungwa kwe-asidi nemvelo ye-alkali.

4. Ukusebenza okuhle kakhulu kokuhlanza: umphumela omuhle wokuhlanza i-countercurrent, ungasetshenziswa ngokuphindaphindiwe, futhi unokuphila kwenkonzo ende (ingahlanzwa ngamanzi aphikisanayo, i-filtrate, i-ultrasonic, i-melting, ukubhaka, njll.).

Kunezigaba ezintathu zenqubo yokukhiqiza i-sintering

1. Isigaba sokushisa esiphansi sangaphambi kokuvutha.Kulesi sigaba, ukubuyiswa kwensimbi, ukuvuthwa kwegesi ye-adsorbed kanye nomswakama, ukubola nokususwa kwe-ejenti eyakha ku-compact kwenzeka ikakhulukazi;

2. Isiteji sokushisa esimaphakathi sokushisa.Kulesi sigaba, i-recrystallization iqala ukwenzeka.Kulezi zinhlayiya, izinhlamvu ezikhubazekile zibuyiselwa futhi zihlelwe kabusha zibe izinhlamvu ezintsha.Ngesikhathi esifanayo, ama-oxide ebusweni ayancishiswa, futhi isikhombimsebenzisi sezinhlayiyana sakha intamo ene-sintered;

3. Ukugcinwa kokushisa okuphezulu kokushisa kuqeda isiteji se-sintering.Ukusabalalisa nokugeleza kulesi sigaba kwenziwa ngokugcwele futhi sekuseduze nokuqedwa, kwakha inqwaba yama-pores avaliwe, futhi kuqhubeke nokuncipha, ukuze ubukhulu bembobo kanye nenani eliphelele lama-pores kuncishiswe, futhi ukuminyana komzimba we-sintered kubaluleke kakhulu. anda.